Subaru Engine Failures | 5 things to look for before it happens

Subaru Engine Failures | Pay attention before things go wrong

[fa icon="calendar'] Jul 30, 2019 6:00:00 AM / by Mike Wiener posted in Subaru Engine Failures

Subaru Engine Replacement | Rod Bearing failure

[fa icon="calendar'] Jun 27, 2019 7:45:06 AM / by Mike Wiener posted in Subaru Engine Failures, iag Subaru Blocks

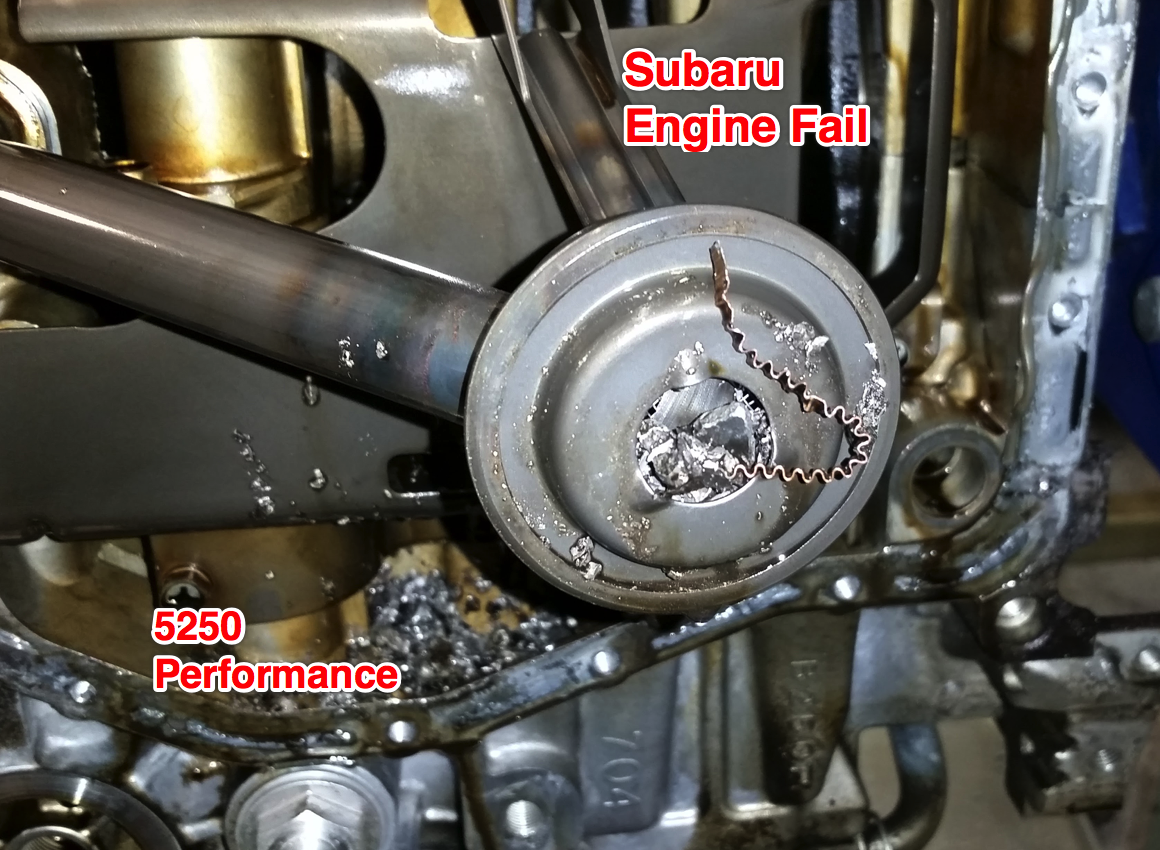

Rod Bearing Failure | Subaru Engine Replacement

Rod bearing failure is common with Subaru Motors. The new FA series even more so than the older EJ series. FA motors are failing at stock power levels. Even mild upgrades require a built motor.

Bearing failure can occur on any motor, at any time, with any oil. The best prevention is to make a properly built motor a priority. Get it right and your motor will last.

Build quality matters more than the oil your use. Proper clearances during the build will prevent bearing failure better than anything else. Stock bearings with proper clearances will last longer than race bearings with bad clearances.

Subaru Engine Failures | a 'built' motor makes more power, but why?

[fa icon="calendar'] Jun 22, 2017 11:00:00 AM / by Mike Wiener posted in Subaru Engine Failures

Subaru Engine Failures | choose performance upgrades wisely

Having a "built" motor means you have replaced some or all of the factory components with upgraded aftermarket ones.

The term "built" is very loose term and varies from only a few improved components to a well built one with major upgrades, choose wisely.

A common thing to do is what is called a piston slap. A new or used stock shortblock has it's pistons removed and replaced with upgraded ones. This is a very economical way to upgrade a motor, but it doesn't always yield the best results.

In the case of a used shortblock, installing new pistons without properly preparing / honing the cylinder walls will cause ring seating problems and engine failure. This is probably the cheapest way to get a "built" motor and you will get what you pay for.

This is where taking shortcuts will lead you to failure | A proper built motor will have the entire rotating assembly upgraded. This includes crankshaft, rods, and bearings in addition to the pistons. There are hundreds of ways to piece these parts together, but all of them should start with a new or newly machined engine block. The cylinder walls must be perfectly round and have the proper cross-hatching for the rings to seat properly.

If the rings don't wear in properly, there will be excessive blow-by and a loss in compression. Improperly seated rings will lead to low power, oil consumption, and failure of the motor.

When building your shortblock, the pistons are the single most critical decision. There are many to choose from and some may not be correct for your application.

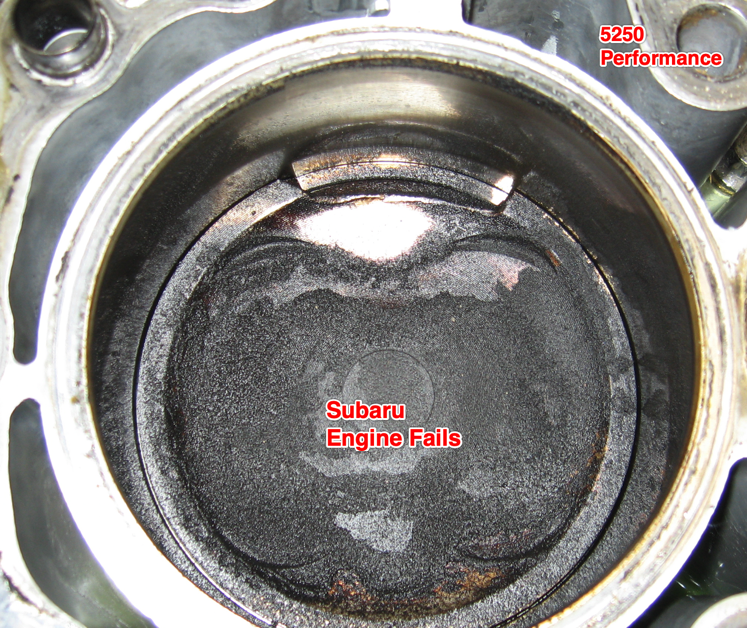

Factory pistons are hyperutectic. This means they are very strong, but very brittle. Similar to a pane of high quality glass, they can take enormous stress loads, but a sudden shock load can cause them to shatter. Detonation, or knock, is the primary killer of pistons. It only takes one fairly mild detonation event to shatter a stock piston.

Aftermarket pistons are of the forged design and are made of a softer material than hyperutectic ones and can handle a sudden knock event without breaking. These are not bullet proof though... a very strong detonation or a series of them can still destroy forged pistons.

When pushing an engine towards higher power, knock will happen. Forged pistons are what allows a tuner to push to the limit, then back off a little bit when that limit is found. Without the ability to take these light knock events, max power cannot be found.

Even on a perfect tune, knock happens. Bad gas or very high operating temperatures can casue a detonation. It's extremely difficult to prevent all knock, so make sure your pistons are up to the challenge, choose your build wisely.