Walnut Blasting | Taking your vehicle in for a “tune-up” used to be a regular maintenance item.

Walnut Blasting | Taking your vehicle in for a “tune-up” used to be a regular maintenance item.

Guess what? It is again if you own a Direction Injection motor.

To keep your engine in tip top shape, you would have to adjust the ignition and fuel systems on a regular basis. If you used gas from a different station or even as the weather changed, you would have to adjust the engine for it to run properly.

As electronics became more and more prevalent on engines, less and less regular adjustments were needed.

There are some modern engines that don't require any service until 20,000 miles, including an oil change. But as new technology emerges, so do flaws in the designs.

One of the biggest changes in modern fuel injected engines is the advent of gasoline direct injection. These engines inject fuel directly into the combustion chamber, much like a diesel engine, although they still rely on a spark plug to ignite the charge.

By introducing fuel only in the combustion chamber, much better control of the fuel air charge is obtained. Issues with puddling fuel in the intake ports is eliminated. In fact, all fuel in the intake ports is eliminated, which can create new problems.

By introducing fuel only in the combustion chamber, much better control of the fuel air charge is obtained. Issues with puddling fuel in the intake ports is eliminated. In fact, all fuel in the intake ports is eliminated, which can create new problems.

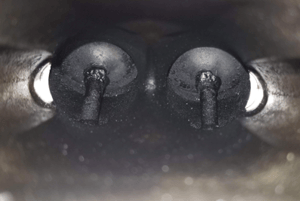

While these new engines are designed to not require any maintenance other than oil changes for 60k miles or more, things aren't going according to plan. In as little as 15k miles, these directly injected engines are developing significant carbon and sludge buildup on the backs of the intake valves.

As the last barrier between the outside world and the combustion chamber, the valves are a very important airflow area.

When searching for more power, headwork is often on the list of work to be done. Oversized valves, 5-angle port jobs, porting, polishing, and cams designed to let the valves open further and longer. All of these things are designed to get more air into the combustion chamber.

Even the back side of the valves and the shape of the valve stems are designed to allow as much air as possible to flow into the combustion chamber. Engineers have even calculated how the air will flow into the combustion chamber and mix with the fuel.

Even the back side of the valves and the shape of the valve stems are designed to allow as much air as possible to flow into the combustion chamber. Engineers have even calculated how the air will flow into the combustion chamber and mix with the fuel.

Now imagine the opposite happening. Slowly obstructing these air pathways with deposits of sludge and carbon. The airflow becomes turbulent and reduced. The fuel doesn't mix evenly and the combustion will not be as complete as possible. You will see this as reduced overall power, reduced fuel economy, poor idle and rough running conditions.

If you have a Direct Injection motor in your vehicle, you need tune-ups again. The only way to properly clean the valves of this buildup is physical cleaning. There are no chemical products that can be easily introduced to the motor to remedy this situation. The intake manifold must be removed and the valves manually cleaned.

The most common method is to media blast the back of the valves with walnut shells and we recommend performing this cleaning every 15,000 to 30,000 miles.

Performance direct injection engines are all prone to build up due to this design, love it or hate it, it is reality. Keep your performance intact, get it maintained with a thorough cleaning.