Walnut Blasting | Having your engine ports cleaned is now available at our Colorado Performance Shop

Walnut Blasting | Having your engine ports cleaned is now available at our Colorado Performance Shop

As manufacturers try to find new ways to increase power and fuel economy, they develop new engine technologies. One technology we are seeing in more and more vehicles is direct injection.

Early engine technology used a carburetor to meter fuel. As air passed through the carb, it caused pressure differences that would allow fuel to be drawn into the airstream. As airflow increased, so did the amount of fuel. Fuel injection was the next big advancement in which precise amounts of fuel were injected into the intake airstream.

By having precise control over how much fuel was added, engines became smoother, more powerful, and more fuel efficient. Direct injection utilizes very high fuel pressure to inject the fuel directly into the combustion chamber. By introducing the fuel just before the combustion event takes place, combustion temperatures are lowered and knock events are greatly reduced. This allows the engineers to design engines with very high compression ratios that increase fuel economy and reduce harmful emissions.

By having precise control over how much fuel was added, engines became smoother, more powerful, and more fuel efficient. Direct injection utilizes very high fuel pressure to inject the fuel directly into the combustion chamber. By introducing the fuel just before the combustion event takes place, combustion temperatures are lowered and knock events are greatly reduced. This allows the engineers to design engines with very high compression ratios that increase fuel economy and reduce harmful emissions.

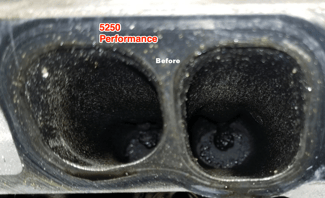

As with many new technologies, some drawbacks are reality. Once these new direct injection motors left the research facilities and got into the hands of regular drivers, it became apparent that these engines would get very dirty, very quickly. Carbon deposits would form on the intake valves within a few thousand miles. If left untreated, these deposits can grow big enough to literally choke the motor. The carbon buildup can block the intake port, making the engine less efficient and a poor performer.

This is a problem with ALL direct injection motors from Subarus to BMWs. We have seen significant buildup in as little as 20,000 miles.

- There are only 2 ways to properly deal with this problem.

The first is to regularly treat the intake system with a chemical cleaner.

This involves spraying a cleaning chemical into the intake tract while the engine is running. Care must be taken as too much chemical too quickly can actually damage the engine. This is a service that most dealerships offer. For it to be effective, it must be done frequently and early, when there is only a residue coating the intake walls..

Once there is buildup on the valves, the chemical cleaning method is not effective and physical cleaning is required.

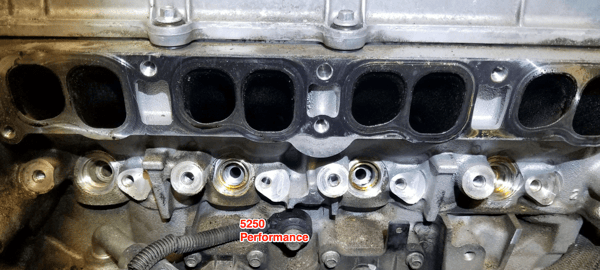

Physical cleaning is the second method of cleaning the intake valves. This process is fairly labor intensive and usually requires removal of the intake manifold. Once access to the intake ports is gained, small tools and picks are used to manually scrape the valves clean. This is is similar to going to the dentist for a regular cleaning.

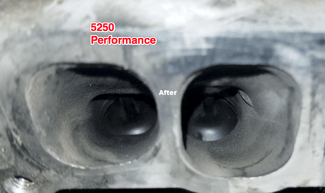

A more efficient way to physically clean these parts is to use a shop that has experience with port cleaning utilizing walnut shells to blast out the gunk and get the valves clean again.

This is similar to sandblasting, but crushed walnut shells are used as the abrasive rather than sand. The walnut is tough enough to clean, but will not damage anything in the engine if some is left behind. Think of walnut blasting as being similar to a teeth whitening service.

If you have a new direct injected motor, we recommend a chemical cleaning every 5000 miles. This will keep the deposits from forming in the first place. If you have not been able to perform regular chemical cleanings, we recommend a walnut blasting service every 20,000 to 30,000 miles. Keeping the intake valves clean will keep your engine breathing well to make the most power and best fuel economy.