Performance Shops know when to create real world solutions ...

Performance Shops know when to create real world solutions ...

...without a hammer & chisel. Want real performance, choose your shop wisely.

Many go fast parts can be bought as a bolt-on solution. This means you don't need to pay the premium for custom work.

But depending on your selection of parts, they may not all meet up or mesh properly. Any build with serious performance goals requires custom fabrication.

Bolt on parts always have a compromise in their design. They have to be made so that they can fit many applications.

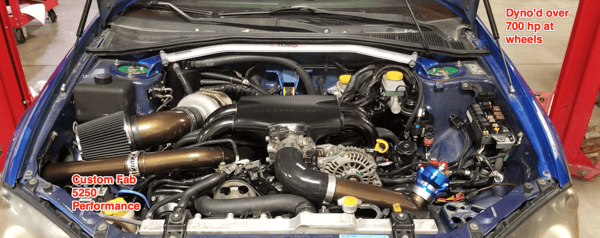

- Custom fabrication is made for your car, your modifications.

If off the shelf parts don't exist for your goals, a good shop knows how to and has the tools / experience to build them

- Once the decision has been made to go custom fabrication, the choices are many. Any look, any color you want.

Every part can be made to work with every other part to attain the end power and drive-ability goals.

The only way to make sure big power goals are attained without sacrificing drive-ability and comfort is to go with a custom solution. There are no bolt-on options that work as a complete system.

The only way to make sure big power goals are attained without sacrificing drive-ability and comfort is to go with a custom solution. There are no bolt-on options that work as a complete system.

There are simply too many options and details when building a big project. Attempting to use only bolt-on parts will end up costing more in the end as certain parts will not work together. Unfortunately, many of these mis-matched parts won't be found until they are mocked up prior to final installation.

Once these issues are found, custom fabrication is usually required to fix the issue. Plan on going custom first and don't waste money buying parts twice. Having experience matters and saves money for all involved.