In the search for more power, everyone wants low end torque and big HP. But when it comes to turbo motors, there is always a trade off.

In the search for more power, everyone wants low end torque and big HP. But when it comes to turbo motors, there is always a trade off.

A smaller turbo will make big low end torque, but fall off in power as the revs climb. A larger turbo will make big power numbers at redline, but is slow to spool and torque suffers.

- If you want smooth power that keeps on building, read on...

This has always been an issue with turbochargers and over the years, engineers have come up with many different ways to make a turbo responsive. They have tried variable vanes, twin-scroll, lightened turbine wheels, and newer computer designed compressor blades.

While these have all made significant improvements in widening the operating range of a turbocharger at stock power levels, larger aftermarket turbos still suffer from significant turbo lag.

If you want the ultimate in quick spool and massive horsepower, there is only one setup that can maximize both. The compound Sequential Turbo.

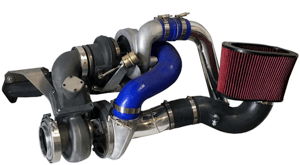

A compound sequential turbo setup combines a quick spooling small turbo with a high power larger turbo. When a compound sequential turbo setup is designed and built properly, you will see boost just off idle and holding strong to redline.

- The plumbing for building turbo systems can be complex and packaging will be tight.

The exhaust leaves the motor and goes into the smaller turbo first, then into the larger turbo and out the tailpipe. Air enters the larger turbo first, then goes into the smaller turbo, then into the engine.

This arrangement allows the smaller turbo to spool up very fast and the larger turbo blowing into it helps move things along. Once the smaller turbo is up to speed, it's wastegate will open.

This wastegate will be significantly oversized compared to the turbo and is plumbed back into the exhaust before the larger turbo. This extra gas flow will spool up the larger turbo which can simply blow through the smaller turbo.

- This configuration does not have complex air valves like many other twin or compound turbo systems.

There are several 90's cars that came with compound turbo systems where one turbo would spool up and then "hand off" to the other turbo. The process of switching turbos was done with air valves directing air around the turbo that was "turning off”.

T he switching process would often cause a very noticeable dip in power in the middle of the rev range. This power dip was often referred to as "The Valley of Death". In a race, you would be pulling away from your rival, only to come in into "The Valley of Death" where you're power would drop and your rival would catch up or even pass you.

he switching process would often cause a very noticeable dip in power in the middle of the rev range. This power dip was often referred to as "The Valley of Death". In a race, you would be pulling away from your rival, only to come in into "The Valley of Death" where you're power would drop and your rival would catch up or even pass you.

You just had to hope that when the second turbo kicks in it's was enough power to hold or regain the lead.

- A compound sequential system supplies a very smooth and linear power curve.

A compound sequential system requires a significant amount of planning to pull off. The two turbos and their waste gates must be sized so they all work together properly and this requires some... math.

- If a compound turbo setup is something you are interested in, we would be happy to do this math for you.

Especially at altitude, a compound turbo setup is the only way to get a BIG hp turbo to spool early and make monster torque.